Storage

AEIS's ability to provide storage for CO2 carbon capture, ethane, propane, butane, isobutane, and natural gasoline (pentanes plus).

NGL and CO2 Storage Opportunities

NGLs are hydrocarbons – in the same family of molecules as natural gas and crude oil, composed exclusively of carbon and hydrogen. Ethane, propane, butane, isobutane, and natural gasoline (pentanes plus) are all NGLs. Use of NGLs spans nearly all sectors of the economy. NGLs are used as inputs for petrochemical plants, burned for space heating and cooking, and blended into vehicle fuel. Significant volumes of NGLs are being produced in the Appalachian region. These resources are often shipped to other domestic markets for use or left unseparated in the natural gas stream, representing unrealized potential. Natural gas liquids are versatile products used in every end-use sector; residential, commercial, industrial (manufacturing and agriculture), transportation and electric power.

The natural gas produced in Appalachia contains valuable resources in the form of natural gas liquids (NGL), including ethane and propane. When separated from the natural gas stream, ethane and propane are key feedstocks for the petrochemical industry, used to produce compounds for making plastics and resins. Appalachian natural gas plant liquids production is projected to increase over 700 percent in the 10 years from 2013 to 2023.

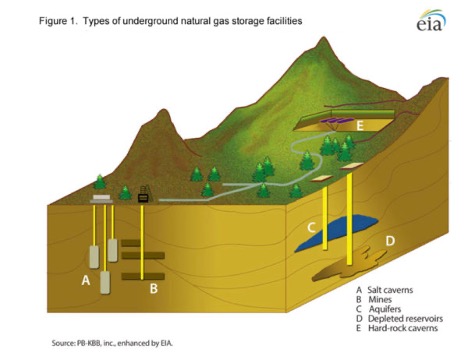

Gas liquids are expensive to handle, store and transport compared to refined products. They require high pressure and/or low temperature to maintain liquid state for shipment and handling. NGL’s also require special trucks, ships, and storage (thick steel insulated tanks, or underground caverns for large volumes. The establishment of an Appalachian gas storage hub is likely to greatly decrease transport costs and increase profitability.

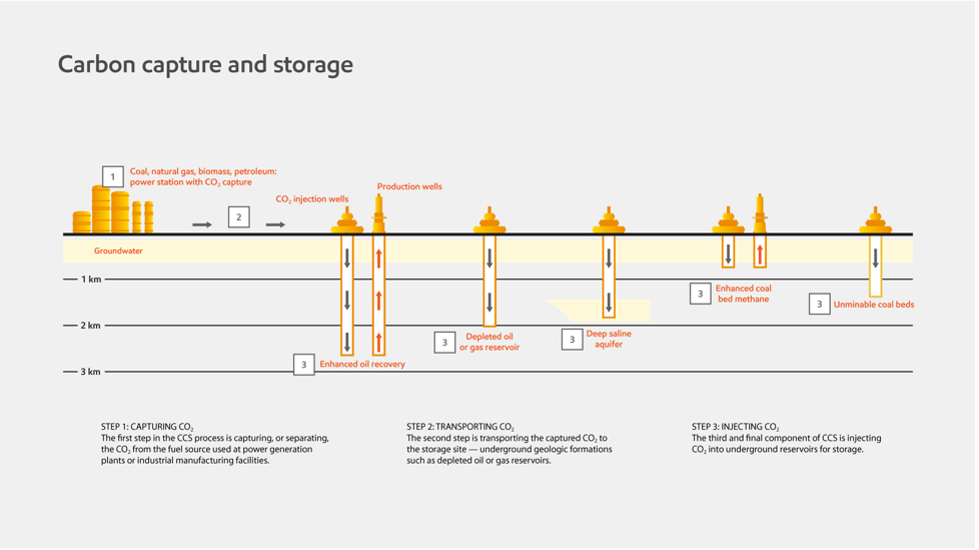

Carbon dioxide (CO2) capture works best when captured as close to the source point as possible.

Carbon dioxide (CO2) capture works best when captured as close to the source point as possible.

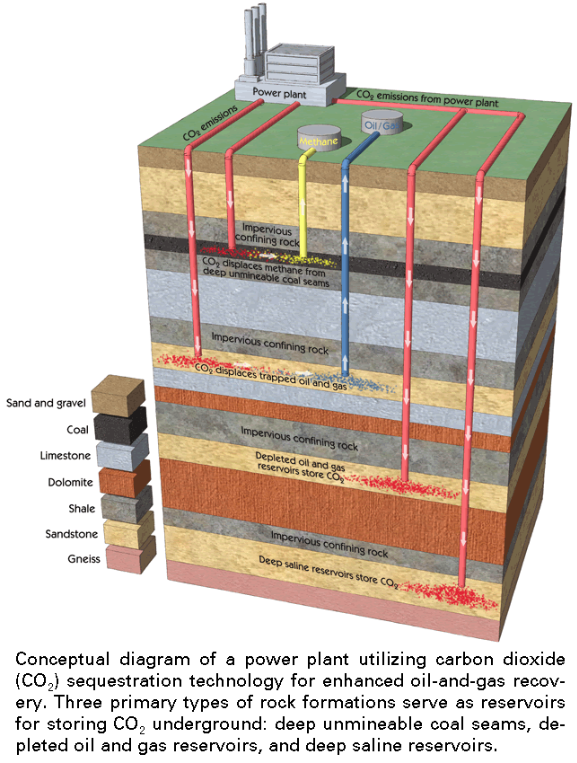

Carbon Dioxide may be captured as a pure by-product in processes related to petroleum refining or from flue gases from power generation. There are three ways that this sequestration can be carried out; post-combustion capture, pre-combustion capture and oxy-combustion. A wide variety of separation techniques are being pursued, including gas phase separation, absorption into a liquid, and absorption on a solid, as well as hybrid processes, such as absorption/membrane systems. These above processes basically capture carbon emitting from power plants, factories, fuel burning industries and so on.

Carbon Dioxide may be captured as a pure by-product in processes related to petroleum refining or from flue gases from power generation. There are three ways that this sequestration can be carried out; post-combustion capture, pre-combustion capture and oxy-combustion. A wide variety of separation techniques are being pursued, including gas phase separation, absorption into a liquid, and absorption on a solid, as well as hybrid processes, such as absorption/membrane systems. These above processes basically capture carbon emitting from power plants, factories, fuel burning industries and so on.

Artificial capture processes of large scale industrially produced C02 have been developed using aging oil fields, subsurface salineaquifers, reservoirs, ocean water or other carbon sinks.

Production Fields with multiple storage options, including CO2

Production Field opportunities include storage and or production from a variety of formations. Proximity and connection to both Tennessee gas pipeline (scheduled for reversal and conversion to NGL) and Texas eastern Pipeline, and Columbia Gas Storage facilities.

- Connections to major pipelines via Columbia gas connections in area.

- “HBP” Held by production Acres with access to all formations.

- Approximately 40-50% depleted Clinton Reservoir.

- Production potential

- Methane Storage Opportunities

Disclosure

Our partnerships acknowledge and disclose that this website was created using publicly available internet resources. The respected institutions mentioned herein are the best at what they do and we appreciate their efforts. The representations throughout this website combines the research and opinions, accessed through publicly available information associated with said institutions.